Intership Report : Multiphysics Modeling with Feelpp CFPDEs Toolbox : Application to the modeling of Lncmi magnets

logo LNCMI

|

Logo UFR Math-Info

|

Logo CEMOSIS

|

author : Vallet Romain

enterprise’s supervisor : Christophe Trophime

school’s supervisor : Christophe Prud’homme

Electromanget of LNCMI : M10

|

1. Introduction

High field magnets are a tool in many research fields such as superconductivity or Biochemistry. Only a few laboratories, including the National Laboratory for Intense Magnetic Fields (LNCMI) in France, supply such magnets, which are made available to the scientific community via calls for projects. LNCMI is a research infrastructure run by the CNRS, located on two sites: Grenoble, where continuous fields up to 37 tesla can be reached during several hours, and Toulouse where pulsed fields up to 100 tesla are achieved within a few hundreds of milliseconds. Their development and maintenance represent a significant cost. This is why it is fundamental to understand and model these magnets beforehand.

In the engineering office the designer of magnet need scientific computes to study the behavior of electromagnet before make them. The mathematic simulations save a lot of time for the team.

My work consist to implement a multiphysic model with a software Feelpp CFPDEs. This implementation permit to automate the computes, saves a lot of time and simplify execution of simulations.

2. Goals

The subject has changed during the intership. The initial subject is Modeling High Temperature Superconductor Magnets. The goals was to implement the classic model of Power Law to study the insert of Supra (a supraconductor magnet). In this intership, I tooke time to develop multiphysic modeling of resistive electromagnet with Feelpp CFPDEs and I didn’t have the time to make the modeling of supraconductor.

The goals of intership become : implement a multiphysic model (elastic, thermic and electromagnetism coupling model) with the software Feelpp CFPDEs.

3. Context

Such High Field Magnets are made of copper alloy since superconductor can only generate up to 25 tesla with the present technology. To obtain an intense magnetic field, it is necessary to pass a sufficiently important current, of the order of 30000 Ampere, in coils. Therefore they have to be cooled down by a forced water flow to dissipate Heat generated by Joule losses. The cooling is usually modelled by heat exchange coefficients, which are introduced as the boundary conditions for the thermal problem. Moreover, the magnets shall withstand the electromagnetic efforts. This calls for multi-physics modelling.

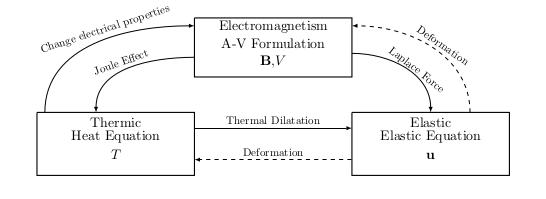

Models for the stationary regime have been developed in the frame of a collaboration between the LNCMI and IRMA. The models heavily rely on the feelpp toolboxes. In this study, we will target a complete axisymmetrical model. In a first part, we will focus on the electromagnetic model - namely a formulation of Maxwell’s equations, in the quasi-static approximation using the formulation in terms of magnetic and electric potential (A-V Formulation). Then, we will present the transient heat model where the the heat source is the Joule losses in the conducting materials (Heat Equation). After, we will consider the coupled electromagnetic and heat problem. Then, we will present the elastic equations which govern the deformations of magnet (Static Elastic Equation, Transient Elastic Equation). Finally we will consider the coupled electromagnetic, heat and elastic problem which result of electromagnetism by Laplace force and result of thermic by thermal dilatation (Elasto-Thermo-Magnetism Equations).

Diagram of Coupling problem

|

The studied models will be implemented using the Coefficient Form PDEs application from feelpp library. This application is highly adaptive, we can implement lot of physic (elastic, heat, Maxwell equation in cartesian, axisymmetry, in static or transient…) and give acces of last features (postproccess, new type of elements…). This application will be briefly presented before going into the details of each model.

4. Work Environment

I worked for a period of six months (February-August 2021) on the LNCMI Grenoble site. I was placed in the U building, a workshop which manufactures the resistive electromagnets and instrumental tools. This proximity to the development and manufacturing team allowed me to quickly understand the challenges of the laboratory.

I was able to talk to my supervisor on a regular basis to resolve the various issues. I had weekly meeting with the CEMOSIS team to present the progress of my work and to solve problems related to the Feelpp software.